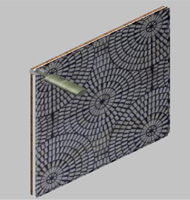

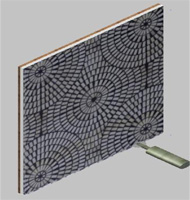

Absound ARCH Stretch fabric panel

This system is a commercial, site-installed, highly customized system for tightly stretching fabric over acoustical or tackable substrates, then applying the panels to the application using a tracking system.

ITEM SPECIFICATIONS |

|

Product name |

Absound Arch Stretch Fabric Panel |

| Installation Procedure |

|

Salient Features

This system is a commercial, site-installed, highly customized system for tightly stretching fabric over acoustical or tackable substrates, then applying the panels to the application using a tracking system. As it is site installed, this system assures a perfect fit to all adjacent work while eliminating any gaps, sagging or misfitting. The tracking is secured to the panel and can be applied to either wall or ceiling applications.

-

Easy to incorporate outlets, switches and lighting.

Easy to incorporate outlets, switches and lighting. -

All work done on site.

All work done on site. -

Perfect tolerance around all architectural situations.

Perfect tolerance around all architectural situations. -

No gaps, sagging or misfitting of fabric.

No gaps, sagging or misfitting of fabric. -

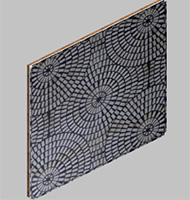

Accepts virtually any fabric.

Accepts virtually any fabric. -

Any depth can be achieved or multiple panel depths can be applied.

Any depth can be achieved or multiple panel depths can be applied. -

Multiple core materials can be used.

Multiple core materials can be used. -

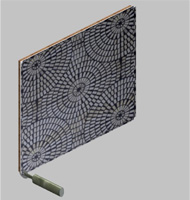

Finished edge is tight to wall.

Finished edge is tight to wall.  Track is not visible under fabric or exposed; flush mounted.

Track is not visible under fabric or exposed; flush mounted. Fabric can be removed for replacement.

Fabric can be removed for replacement. -

Fabric is stretched, not glued; allows for high tension applications.

Fabric is stretched, not glued; allows for high tension applications.

Applications

-

Auditoriums

Auditoriums -

Studios

Studios -

Cinema Theatres

Cinema Theatres -

Recording Rooms

Recording Rooms -

Conference Rooms

Conference Rooms

installation procedure

- 1. Field measure each wall area which is to receive the acoustical tackable treatment to

establish the exact layout of the units. - 2. Apply the stretch wall fabric framework in the areas to receive the acoustical wall treatment as

shownin the figures. - 3. Secure the framework with suitable mastic and special, heavy -duty,

one-inch fasteners located not more than 2" on center. - 4. Install the Stretch Wall fabric System framework plumb and straight, flush in proper alignment.

- 5. Install the sub-surface material, continuous and flush to the shoulder of the track.

- 6. Cut the fabric from each roll marking and maintaining sequence of drops and matching

the direction of the weave for sequential and uniform installation. - 7. Install the fabric from the face side after the framework is security fastened to ensure perfect

horizontal and vertical grain alignment. - 8. The fabric shall be stretched tautly, evenly and smoothly and will be free of defects and flaws.

- 9. No stapling or gluing of fabric to core or channels will be permitted.

- 10. Penetrations through the face of the fabric of any kind ( i.e. staples, nails, etc.) will be prohibited.

- 11. Pre - wrapped, prefabricated or wood ground systems do not meet the intent of this specification.

- 12. Z-clip, Velcro® or glued installation techniques do not meet the intent of this specification.

- 13. Sewn seams of any type do not meet the intent of this specification.

- 14. Installation shall be timely and installers shall be courteous and cooperate with other trades.

- 15. No substitution of our Stretch Wall Fabric System shall be permitted.

Steps

|

|

|

| Step-1 | Step-2 | Step-3 |

|

|

|

| Step-4 | Step-5 | Step-6 |

|

|

|

| Step-7 | Step-8 | Step-9 |

|

|

|

| Step-10 | Step-11 | Step-12 |

![]() Product Range

Product Range